CastIronAnalysis.GJS/GJV

>> mehr ...OptiMa.CastIronAnalysis

- Microstructural analysis of spheroidal/ vermicular and lamellar graphite cast irons.

- Determination of the ferrite/pearlite ratio

- DIN EN ISO 945 and ASTM-A247

Cast iron materials are distinguished not only in terms of the shape and structure of their graphite deposits, but above all in terms of the directly related mechanical properties, such as tensile and compressive strength, modulus of elasticity, shear strength and other material characteristics which, in conjunction with the design geometry, have a significant influence on the quality of a cast iron part.

The relevant standards for assessing the quality of cast iron products are DIN EN ISO 945 and ASTM A247. According to these standards, the classification and evaluation of a material sample must be carried out by visual evaluation. Although still common practice in many places at present, this procedure is nevertheless very error-prone and by no means unambiguous. For this reason, modern software-based methods for quantitative microstructural analysis are now an integral part of metallographic practice, although this development is certainly not yet complete.

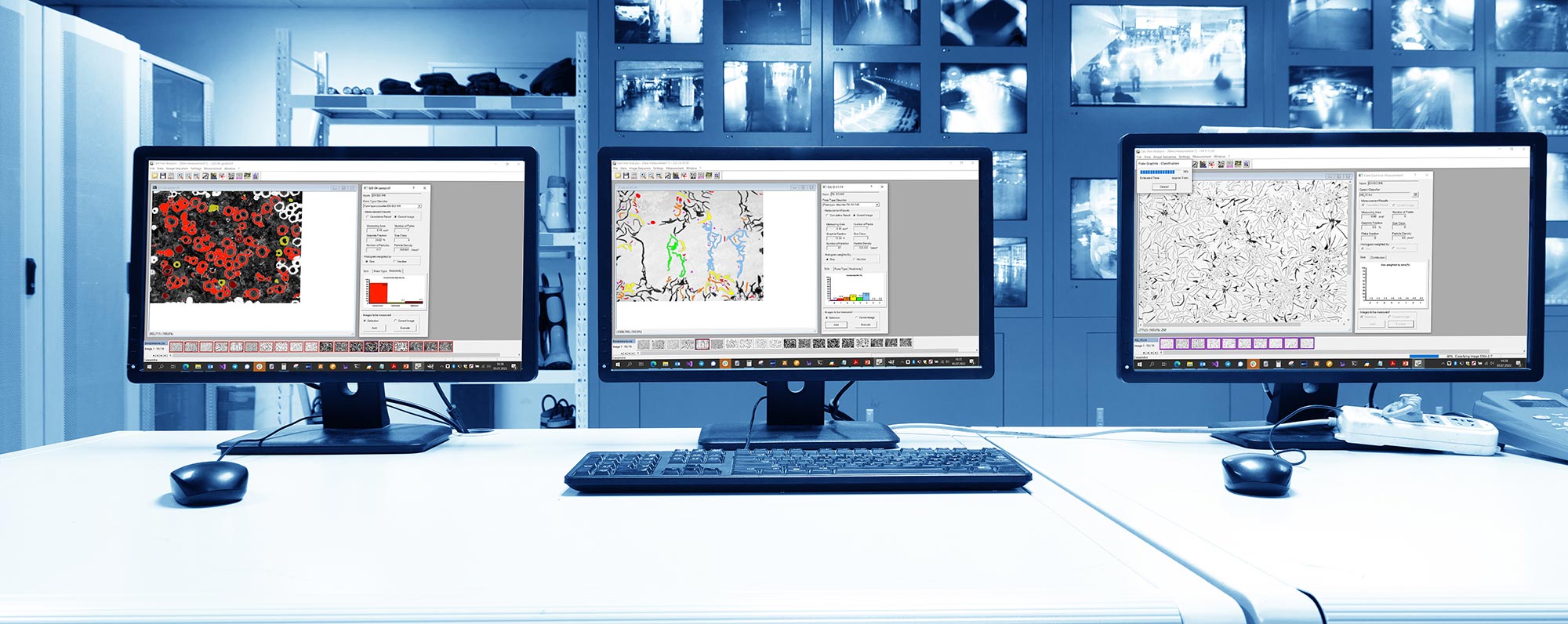

Against this background, the AMGuss software was developed. Since 2006, it is used worldwide by renowned foundries and other industrial companies for efficient quantitative analysis of cast iron works as part of quality assurance, and is now known under the name of OptiMa.CastIronAnalysis. Since in practice it also happens that companies have an evaluation interest limited exclusively to a certain mold class, the module itself has been divided into two further submodules (OptiMa.CastIronAnalysis.GJS/GJV and OptiMa.CastIronAnalysis.GJL), which are also available separately:

Downloads: